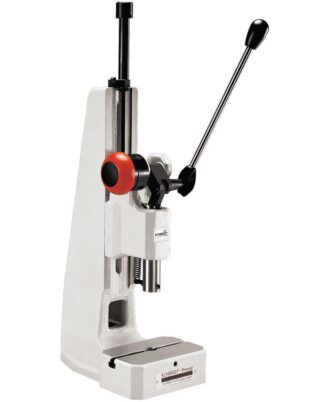

Features

* High force at the end of stroke (see diagramm below)

* Honed bores and ground rams provide a long service life and a precise guidance

- Rapid changeover due to the easy and secure adjustment of the working height

* Table tops with precision T-slot and precise alignment between the ram and table bores allow for accurate and repeatable set ups which reduces set-up times

* The original position of the hand lever can be varied by 360°

* Horizontal pull (111 / 113)

* Available for left-handed and right-handed use

* The return stroke force of the ram can be adapted to different tool weights

* Alignment < 0.05 mm between upper and lower tool

* No lubrication necessary

5 to 15 kN Technical Data

| Press type | | | 13

13F | 13R

13RF | 11

11F | 11R

11RF | 15

15F | 15R

15RF | 14

14F | 14R

14RF | 16

16F | 16R

16RF | 17

17F |

|---|

| Press head type | | | 13-40

13F-35 | 13R-40

13RF-35 | 11-45

11F-35 | 11R-45

11RF-35 | 11-45

11F-35 | 11R-45

11RF-35 | 11-60

11F-50 | 11R-60

11RF-50 | 11-60

11F-50 | 11R-60

11RF-50 | 11-20

11F-20 |

| Nominal force | | kN | 5 | 5 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 15 |

| Working stroke5) | A | mm | 40

35 | 40

35 | 45

35 | 45

35 | 45

35 | 45

35 | 60

50 | 60

50 | 60

50 | 60

50 | 20

20 |

| Throat depth | C | mm | 65 | 65 | 86 | 86 | 86 | 86 | 86 | 86 | 86 | 86 | 86 |

| Press head height | S | mm | 385

400 | 385

400 | 520

540 | 520

540 | 520

540 | 520

540 | 500

520 | 500

520 | 500

520 | 500

520 | 620

640 |

| Ram bore | Ø | mm | 10 H7 | 10 H7 | 10 H7 | 10 H7 | 10 H7 | 10 H7 | 10 H7 | 10 H7 | 10 H7 | 10 H7 | 10 H7 |

| Left hand lever | | | O | | O | | O | | O | | O | | |

Max. Weight of upper tool 3)

standard / reinforced spring | | kg | 1.2 / 3.5

1.5 / 3 | 1.2 / 3.5

1.5 / 3 | 2 / 4.5

2.5 / 6 | 2/4

2/6 | 2 / 4.5

2.5 / 6 | 2/4

2/6 | 1.5 / 2.5

2/5 | 1.5 / 2.5

1.5 / 4 | 1.5 / 2.5

2/5 | 1.5 / 2.5

1.5 / 4 | 2.5 / -

2.5 / - |

| Return stroke lock1) | | | | | | | | | | | | | |

|---|

| Minimum working stroke | | mm | | 25 | | 20 | | 20 | | 24 | | 24 | |

| Locked position 1 | | mm before DC | | 13.5 | | 12 | | 12 | | 14 | | 14 | |

| Locked position 2 | | mm before DC | | 1.5 | | 1.5 | | 1.5 | | 1.5 | | 1.5 | |

| Disengaging accuracy | | mm | | 0.03 | | 0.03 | | 0.03 | | 0.04 | | 0.04 | |

| Working height 4) | F | | | | | | | | | | | | |

| Stand No. 13 | | mm | 65-180

40-155 | 66-180

40-155 | | | | | | | | | |

| Stand No. 3 | | mm | | | 75 - 210

50 - 185 | 75 - 210

50 - 185 | | | 90 - 220

65 - 195 | 90 - 220

65 - 195 | | | 65 - 200

50 - 185 |

| Frame No. 5 | | mm | | | | | | | | | | | 65-315

50-300 |

| Frame No. 2 | | mm | | | | | 100 - 345

80 - 325 | 100 - 345

80 - 325 | | | 110 - 360

85 - 335 | 110 - 360

85 - 335 | |

| Frame No. 2-600 O | | mm | | | 200-585

175-560 | 200-585

175-560 | 200-585

175-560 | 200-585

175-560 | 210-595

185-570 | 210-595

185-570 | 210-595

185-570 | 210-595

85-570 | 200-585

175-560 |

| Frame No. 2-1000 O | | mm | | | 330-1020

305-1000 | 330-1020

305-1000 | 330-1020

305-1000 | 330-1020

305-1000 | 340-1030

315-1010 | 340-1030

315-1010 | 340-1030

315-1010 | 340-1030

315-1010 | 330-1020

305-1000 |

| Weight | | approx. kg | 12 | 13 | 23 | 24 | 29 | 29 | 24 | 24 | 29 | 29 | 23 |

| Accessories | 13

13F | 13R

13RF | 11

11F | 11R

13RF | 15

15F | 15R

15RF | 14

14F | 14R

13RF | 16

16F | 16R

16RF | 17

17F |

|---|

| Mechanical counter | O | O | O | O | O | O | O | O | O | O | O |

| Projection adaptation (total projection) 111 mm, 131 mm | | | O | O | O | O | O | O | O | O | |

Additional table top suitable for

projection adaptation | | | O | O | O | O | O | O | O | O | O |

| Stop clamp 2) | O

O | O

O | •

• | •

• | •

• | •

• | O

O | O

O | O

O | O

O | •

O |

| Shortening the working stroke | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Stand overview | Press type | Stand height

M (mm) | Table size

W x D (mm) | Table bore

D (Ø mm) | Table height

K (mm) | Footprint

W x L (mm) |

|---|

| No. 13 | 13 | 475 | 110 x 80 | 20 H7 | 46 | 110 x 185 |

| No. 3 | 11, 14, 17 | 540 | 150 x 110 | 20 H7 | 60 | 150 x 260 |

| No. 5 | 17 | 536 | 185 x 110 | 20 H7 | 60 | 185 x 275 |

| No. 2 | 15, 16 | 700 | 185 x 110 | 20 H7 | 60 | 185 x 280 |

| No. 2-600 | 11, 14, 15, 16, 17 | 974 | 200 x 160 | 20 H7 | 98 | 200 x 290 |

| No. 2-1000 | 12, 14, 15, 16, 17 | 1410 | 200 x 160 | 20 H7 | 98 | 200 x 290 |

| Options |

|---|

| • Standard at no extra charge O variant with surcharge |

| 1) Adjustment of the locking position possible on request |

| 2) Stroke shortened by 10 mm for variant at extra cost |

| 3) Weight was determined in hand lever position 45 ° forward (guide values) with standard stroke (not special stroke) |

| 4) Typical values; can deviate by ± 3 mm due to casting and manufacturing tolerances |

5) Stroke adjustable with stop clamp (in the scope of delivery) |

| Special designs |

|---|

| Nickel-plated version for a surcharge, press frame, cast parts and table top chemically nickel-plated, steel parts burnished, aluminum parts anodized, polished components bright |

| Special painting RAL colors |

| Special table bores and special ram bores on request |