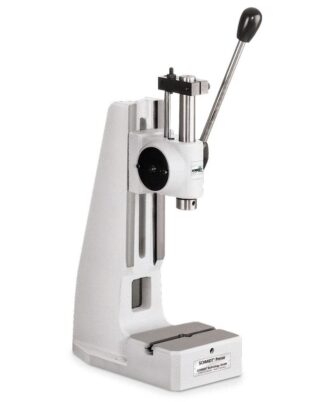

SCHMIDT® ServoPress

Forces from 1 kN to 250 kN

An economic and high quality assembly is the key to the success of your product. The aim is to join together precise assemblies from low-cost individual components with different tolerances. Electrically driven spindle presses, servo presses, are ideal for such tasks. SCHMIDT® ServoPress systems offer an integrated solution of SCHMIDT® PressControl 700 or PressControl 7000 control unit and SCHMIDT® ServoPress modules. They meet the most complex requirements, as stand- alone machines or in automatic production lines.

SCHMIDT® ServoPress work with a real force controller (force as a controlled variable) and thus enable:

- Quick achievement of the setpoints

- No exceeding of the target values

- Precise positioning in the 1/100 mm range, even with strongly fluctuating press-in forces

- Highly accurate, continuous force control

- optimal adaptation to your application

- the system works with preset optimal acceleration values (no incorrect entries possible)

Highest precision through dynamic deflection compensation

In order to enable joining in the 1/100 mm range, the system elasticity must be compensated. During the production of press connections, the workpiece, tool and machine are elastically deformed by the forces acting on them. After the system has been relieved of pressure, this part of the deformation rebounds. This means that the workpiece is “longer” than in the block position when the pressing force is applied. In the case of strongly fluctuating press forces, it is therefore impossible to produce high-precision joints even if the block position is reproduced exactly. This elasticity can therefore be taken into account in a ServoPress, so that the system dynamically and reliably compensates for all minor movements and deformations that occur.

Machine self-protection

- Fully automatic spindle lubrication