Machine exhibition Motek 2021

Machine exhibition Motek 2021 When Motek opens its doors again in Stuttgart from October 5 to 8, we from SCHMIDT Technology will also be there and look forward to welcoming you analogously and personally. The good made even better In order to be able to implement your requirements even faster and more precisely, SCHMIDT Technology has developed fundamentally rethought control systems which, with their modern operating concept and high flexibility, offer a level of intuitive operation that is downright fun to use.

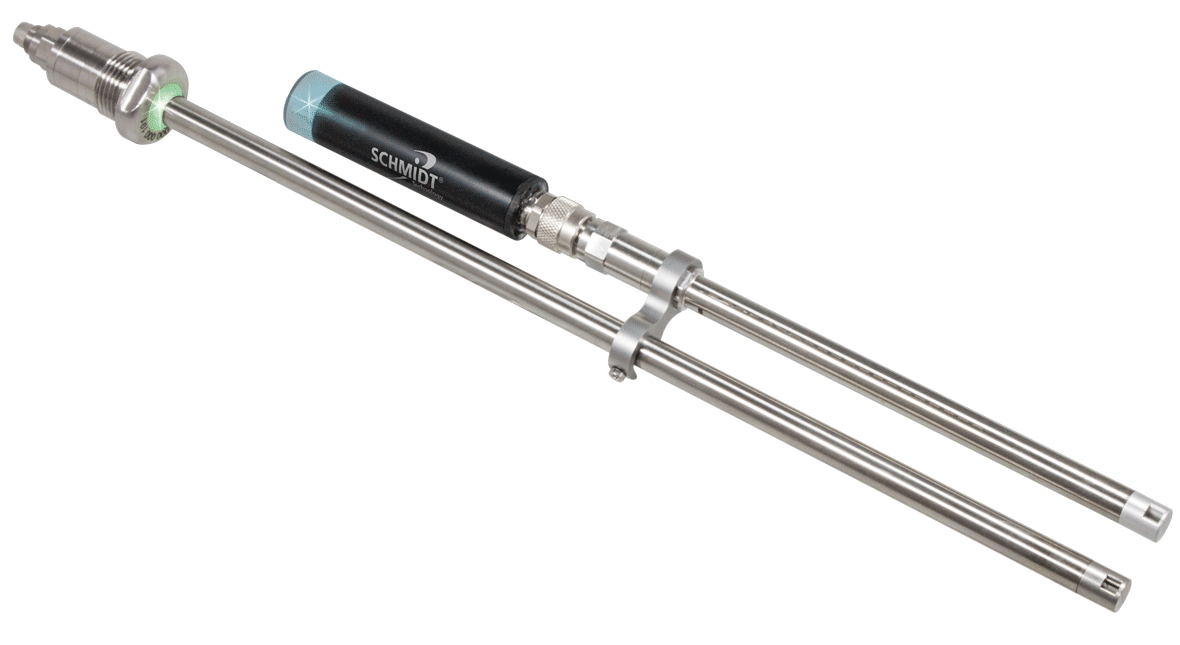

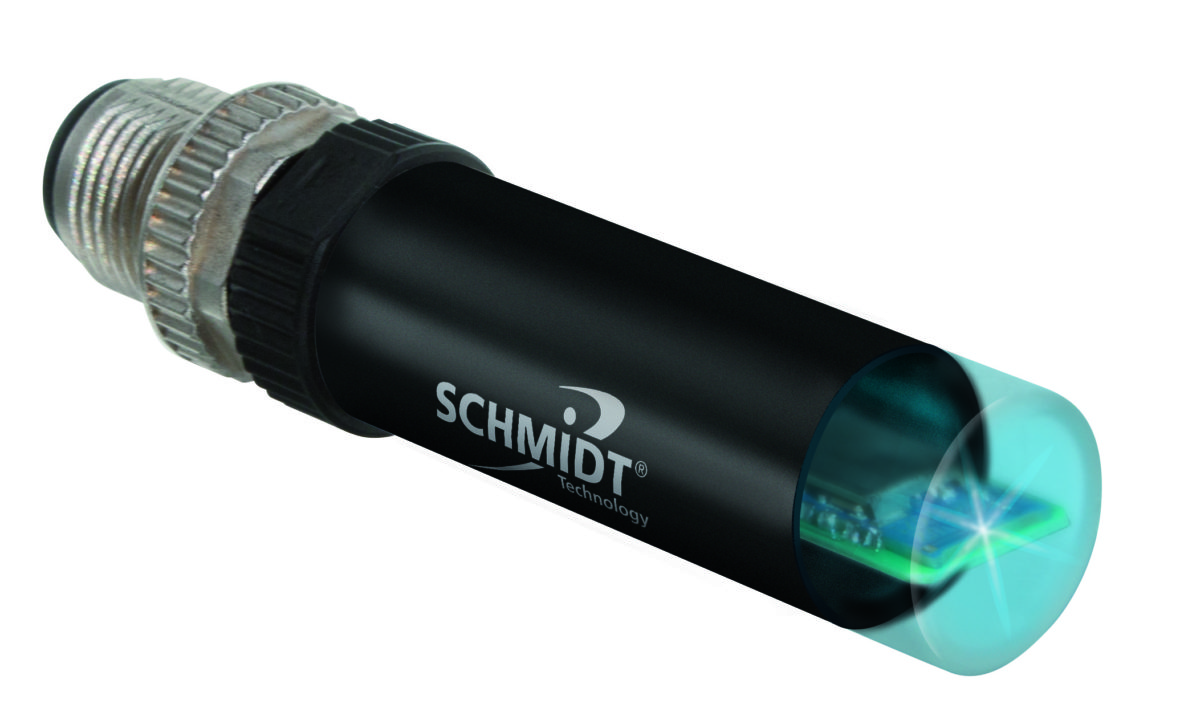

The flagship of our press program, the ServoPress series has been intensively revised and inspires with even more power and precision with unmatched reliability. Get to know the new modules also in the context of our extensive range of safety concepts.

As a further highlight, experience the premiere of our new patented press technology in the field of hand lever presses. With its unique kinematics, the cam press combines the advantages of a toggle press with those of a rack and pinion press. The result is our benchmark for ergonomics and efficiency.

As you can see, we have used the past 2 years to generate quite a few innovations. We therefore personally invite you to match our latest products with the requirements of your applications and look forward to your visit in Hall 3, Booth 3316. Kind regards

Thomas Brodbek, Sales Manager Global

Klaus Grießhaber, Sales Manager Germany and Italy