Flow measurement in harsh conditions

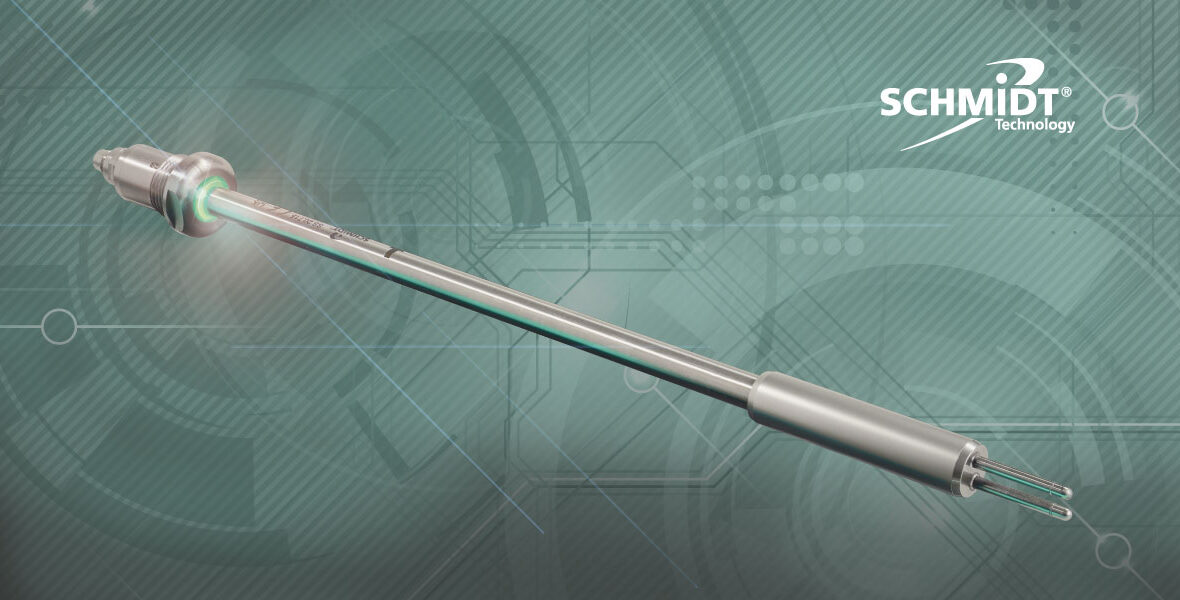

The SCHMIDT® flow sensor SS 20.700 is a robust solution for highly demanding heavy-duty applications in air and other gases. With sensor elements completely encapsulated in stainless steel, it impresses with its resistance to aggressive media and dirt.

Flow rates of gases – an important parameter in industrial processes

Energy saving and quality assurance measures are becoming increasingly important in the production process of industrial processes. The precise measurement of volume flows and flow rates of the gases plays a major role. The requirements for the intended flow sensor are high: The sensor should deliver precise measurement results in different gases, high overpressures and wide temperature ranges - even under the most difficult environmental conditions. Another criterion when choosing the right sensor is the avoidance of maintenance and high follow-up costs. Users want easy installation and reliable readings over the years. Robust solution for heavy-duty industrial processes and compressed air technology

The thermal SCHMIDT® flow sensor SS 20.700 is the robust solution for extremely challenging industrial applications. It can be used for various applications such as compressed air monitoring, gas monitoring for process burners, metering of gas consumption and much more. The double pin sensor was designed precisely to meet the needs of so-called "heavy-duty applications" and is ideally suited for demanding applications such as e.g. B. the production of bio-gas. In addition, the sensor is resistant to aggressive media. In addition to the flow velocity, the SS 20.700 also records the medium temperature up to +120 °C. It can be used in small pipes from DN 40 and can also record the volume flow in large ducts up to a sensor length of 600 mm. The sensor can be used up to an overpressure of 16 bar. The installation of the sensor is very easy: Screw in the sensor using the supplied through-bolt, align it in the gas flow and in the middle of the pipe, connect electrically - done. The sensor works without moving parts and due to the measuring principle, drift or aging are irrelevant. Due to the sensor elements being completely encapsulated in stainless steel, the maintenance of the sensor is reduced to an absolute minimum. However, should cleaning be necessary, this can be carried out very easily and in a variety of ways - in the spirit of "heavy-duty".

High gas velocities and special gases

The special double pin sensor head records flow velocities from 0.1 m/s up to 220 m/s. In order to obtain precise measurement results in this very wide speed range, each sensor is individually adjusted in a high-quality pressure wind tunnel. The sensor can be supplied in individual versions for use in different gases, e.g. B. for pure oxygen, nitrogen, argon, CO2 and other gases.

Individually adapted to each application There are 2 standard sensor lengths to choose from for optimum installation in different pipe diameters. The SS 20.700 can also be ordered in a remote version for difficult installation conditions. The standard sensor lengths are available here, the cable length between sensor and housing can be freely defined (up to 10 m). In addition to various standard measuring ranges, the flow sensor can also be supplied with an application-specific measuring range. For media with an oxygen content of > 21% by volume, all parts that come into contact with the medium must be cleaned of grease, oil or other combustible components. Two special variants "Oxygen O2 > 21%" and "Fat-free and oxygen O2 > 21% (LABS-free)" provide the necessary security for these applications.

Modular function extension

In addition, the SS 20.700 has a module interface as standard for the modular expansion of the sensor's range of functions. The sensor can be parameterized via the module interface, a Bluetooth® wireless transmission to the SCHMIDT® Sensor App can be implemented or the additional 7-segment display MD 10.020 can be connected. The SCHMIDT® data logger DL 10.010 can also be operated via the module interface. The module interface also has an LED light ring, which signals communication with other additional modules by means of different colors and pulsing. The sensor parameterization enables e.g. B. a scaling of the measuring range to individual needs, the settingment of a damping and much more.

Highlights of the SCHMIDT® flow sensor SS 20.700: Sensor elements completely encapsulated in stainless steel

Large flow measurement range from 0.1 to 220 m/s

Temperature measurement range from -20 to +120 °C

For air and gases in applications with harsh conditions (medium with aggressive components, pollution, high humidity)

Very robust design and overpressure resistant up to 16 bar

Easy cleaning thanks to the encapsulated stainless steel surface

Sensor configuration via module interface SCHMIDT® flow sensor SS 20.700: Especially designed for "heavy-duty applications": Thanks to the sensor elements completely encapsulated in stainless steel, they are ideal for demanding applications such as e.g. B. the production of bio-gas etc. Suitable and resistant to aggressive media.